Is there a feasible way to produce metal products on the moon? That’s the question NASA asked university students in its 2023 Breakthrough, Innovative, and Game-changing (BIG) Idea Challenge. And a team of U materials science and engineering students answered with a winning proposal.

Is there a feasible way to produce metal products on the moon? That’s the question NASA asked university students in its 2023 Breakthrough, Innovative, and Game-changing (BIG) Idea Challenge. And a team of U materials science and engineering students answered with a winning proposal.

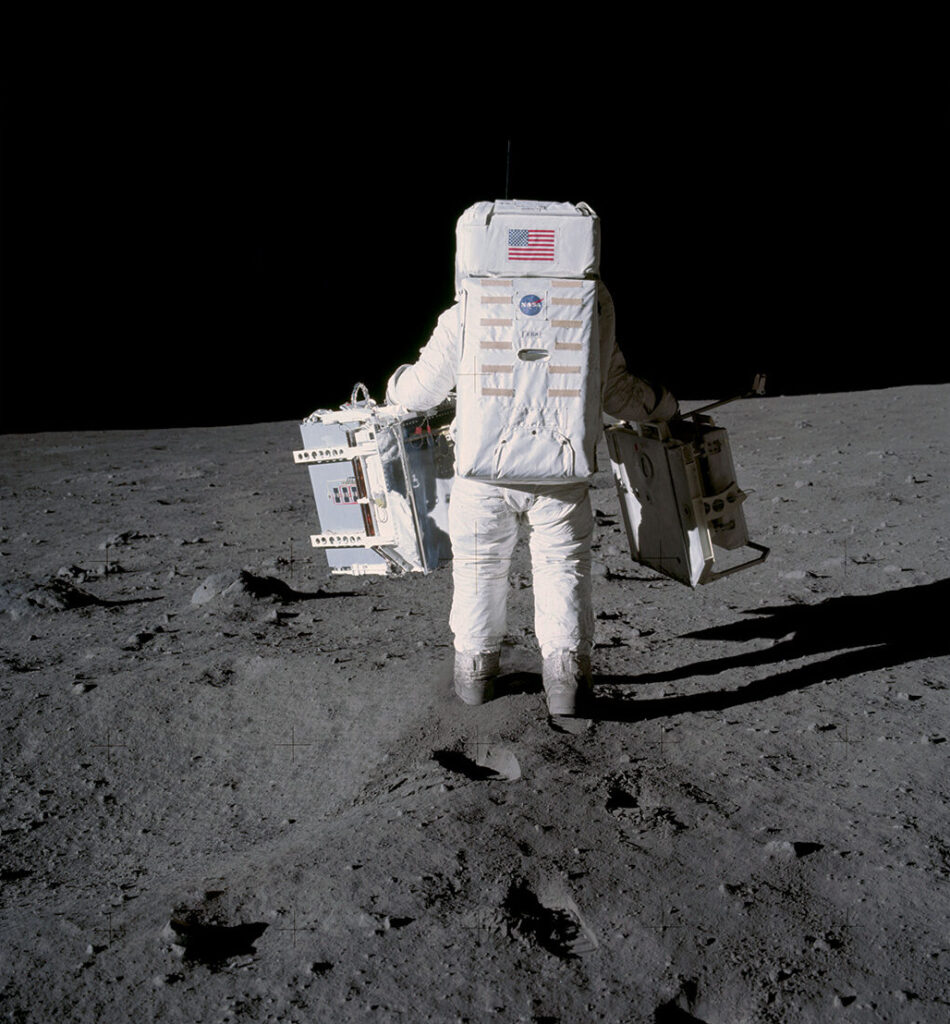

NASA’s Artemis program aims to set up a permanent lunar base, and the challenge offered winning teams up to $180,000 to design, develop, and demonstrate technologies for producing building materials from moon-sourced metals.

“Transporting metal to the moon is difficult and expensive,” explains doctoral student John Otero, who co-led the team. “Fortunately, the moon’s surface is relatively rich in iron.” The team turned to a method called iron carbonyl refining, which already produces iron powder for fortified cereal, vitamin supplements, and a few other uses.

“We realized that the advantages of the process pair incredibly well with the lunar environment,” says doctoral student and team leader Collin Andersen. The students proposed a setup small enough to fit inside a living room, in which iron is pressurized with carbon monoxide to become a gaseous compound. Then it’s heated, causing the iron particles “to fall down like a light snow,” says Andersen. “It’s a very fine powder perfect for 3D printing. Then all it takes is sandblasting or some other kind of finishing, and you’ve got yourself a full part.”

After receiving the challenge’s top honor—the Artemis Award, given for the concept with the greatest lunar-mission potential—the U team is hopeful their idea will someday land on the moon.

Comments

Comments are moderated, so there may be a slight delay. Those that are off-topic or deemed inappropriate may not be posted. Your email address will not be published. Required fields are marked with an asterisk (*).